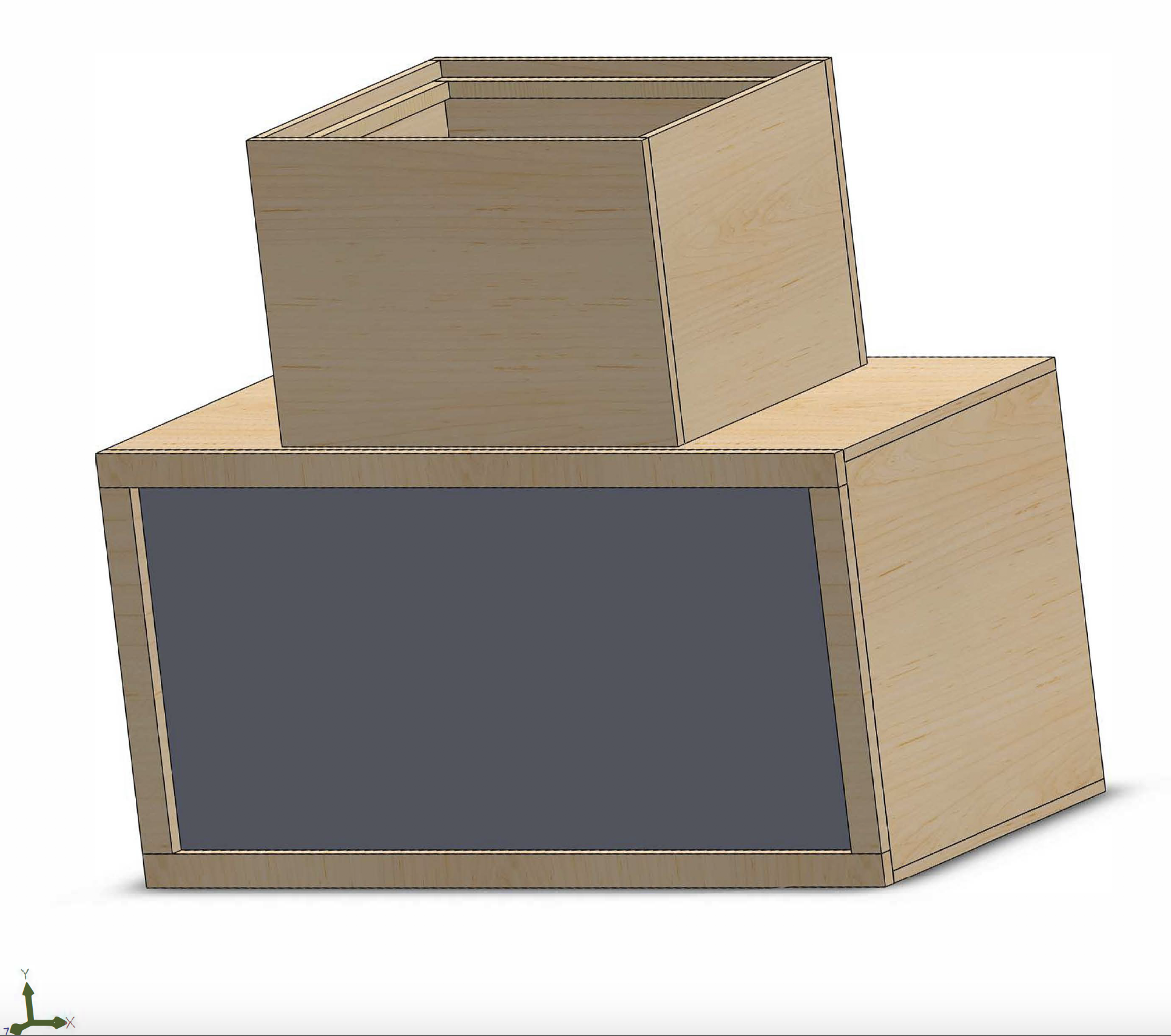

laminar flow hood build

something I never imagined I would be doing

Despite studying chemical engineering, aka glorified plumbing— where we spend months learning about laminar flow— I never thought I’d find myself performing engineering calculations necessary to achieve it. I was a bio person? But! Fluids was my favorite class anyways, so I was up for the refresher challenge.

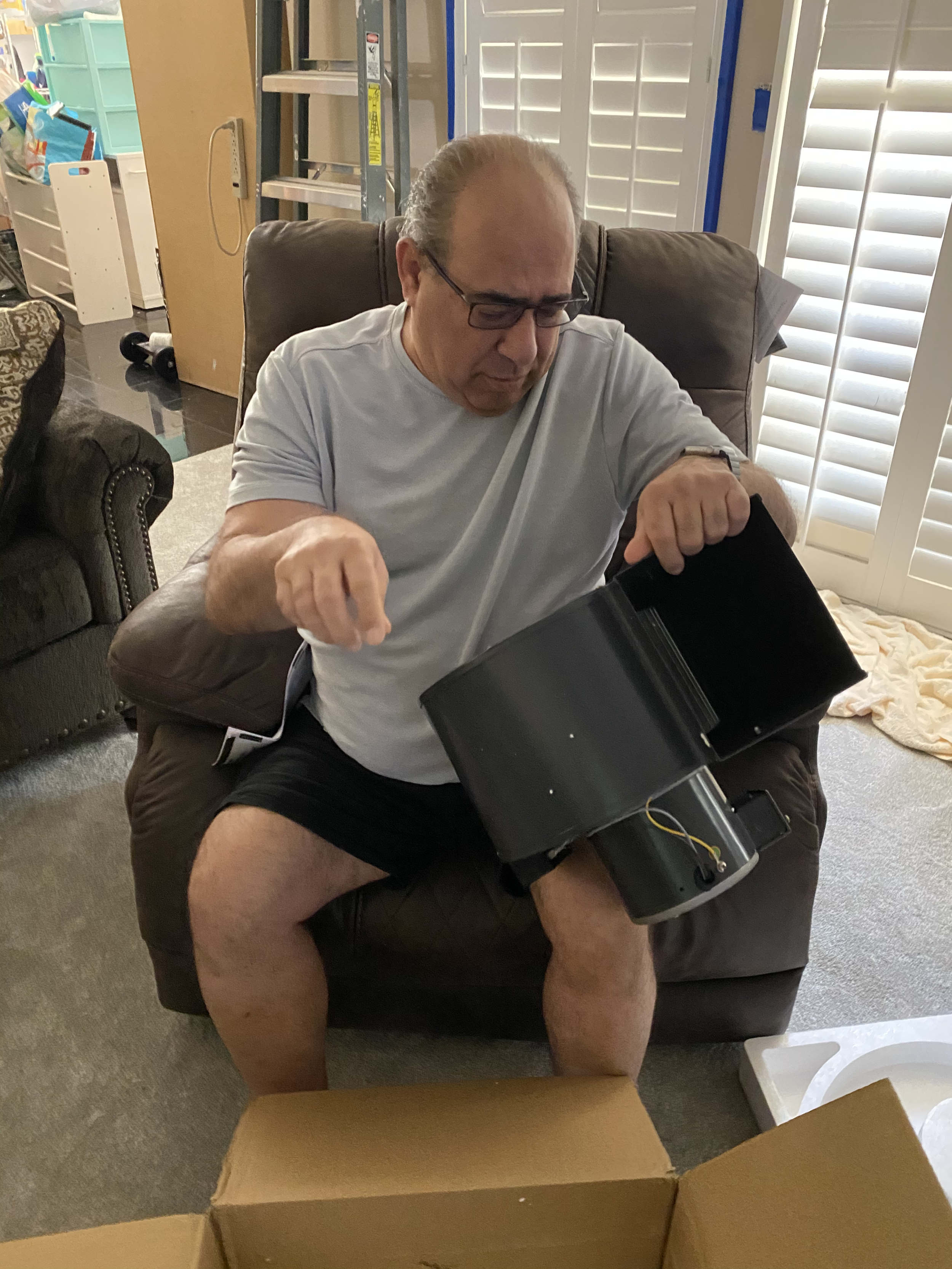

why is my dad the best?!

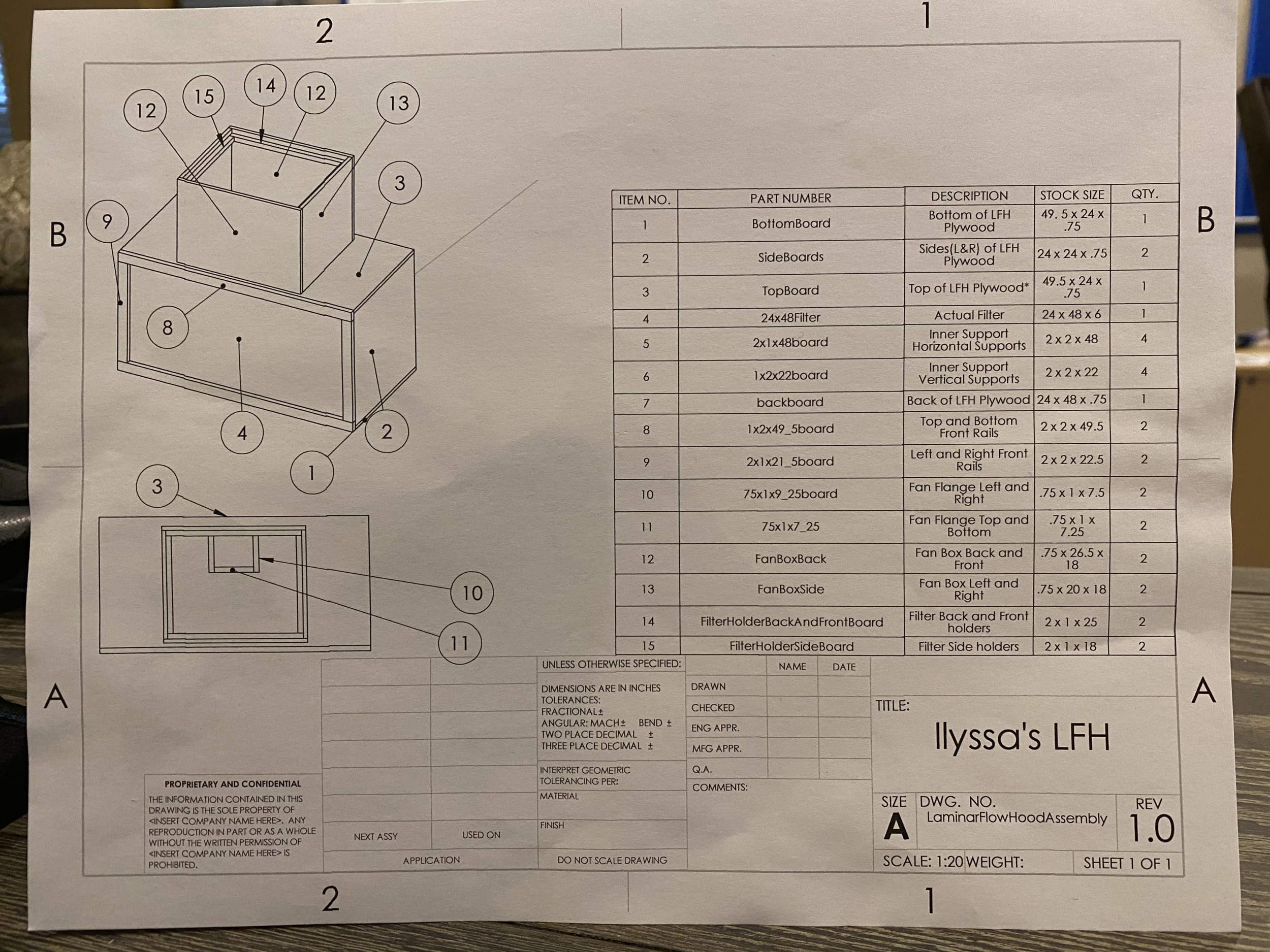

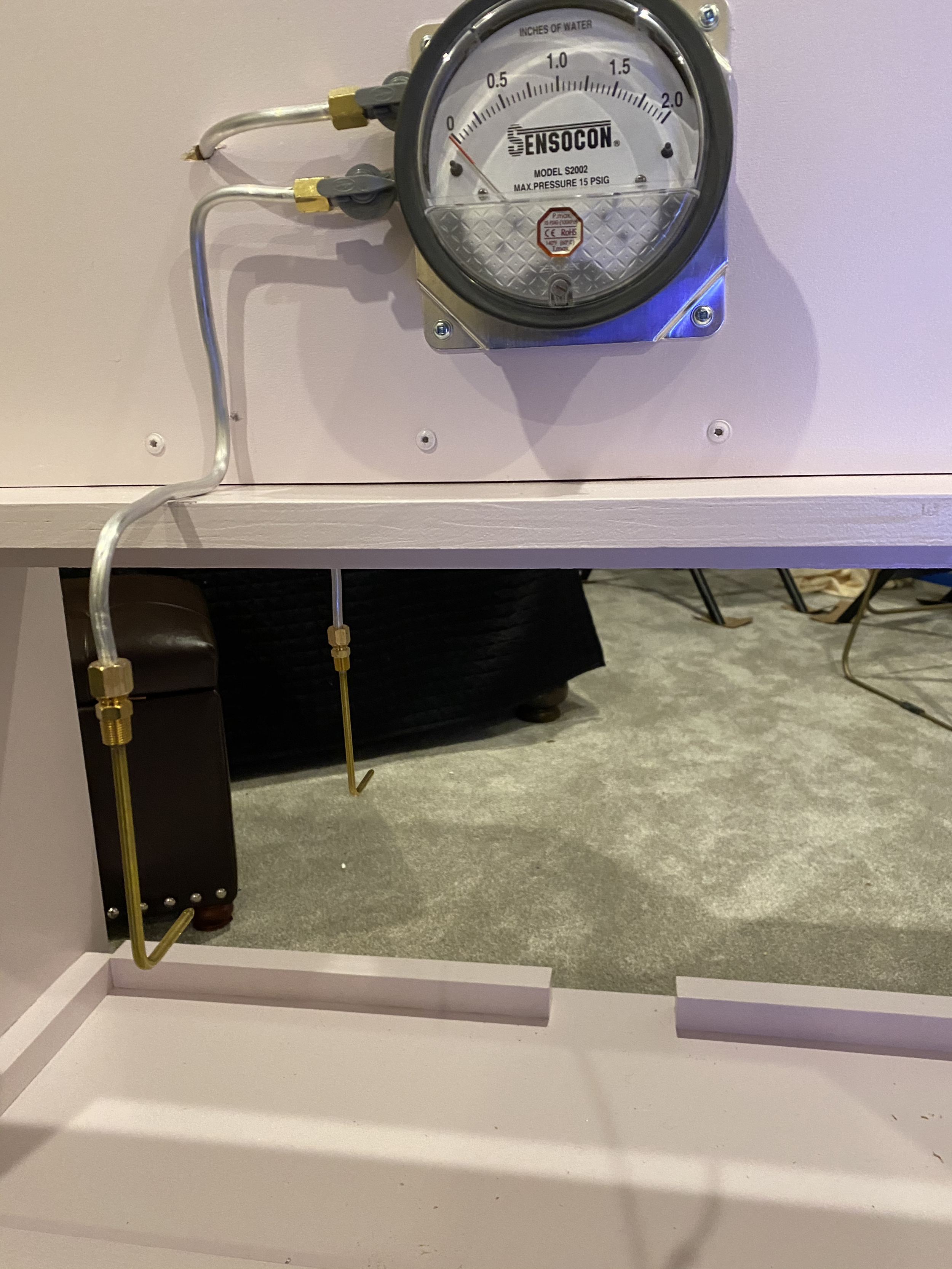

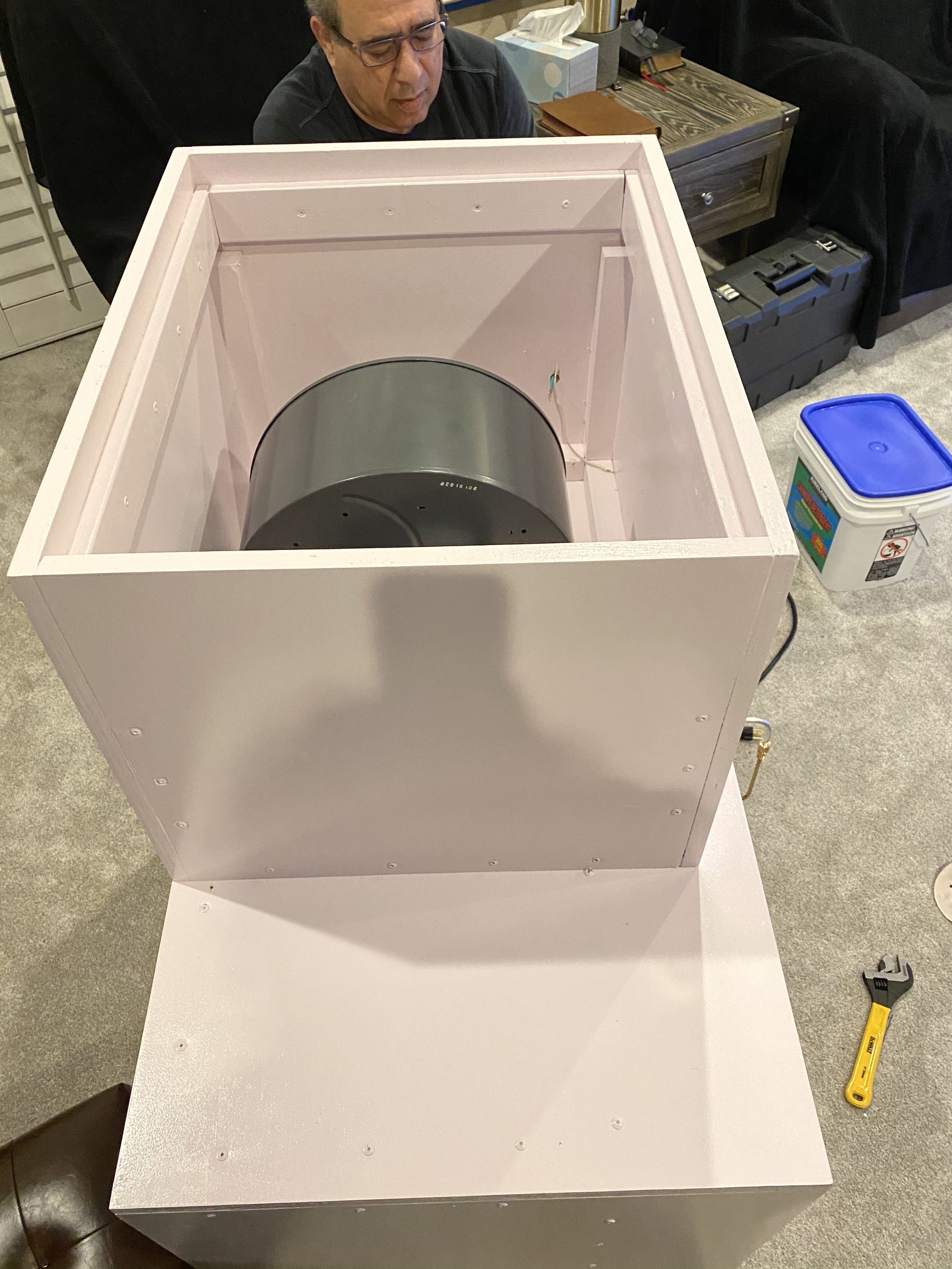

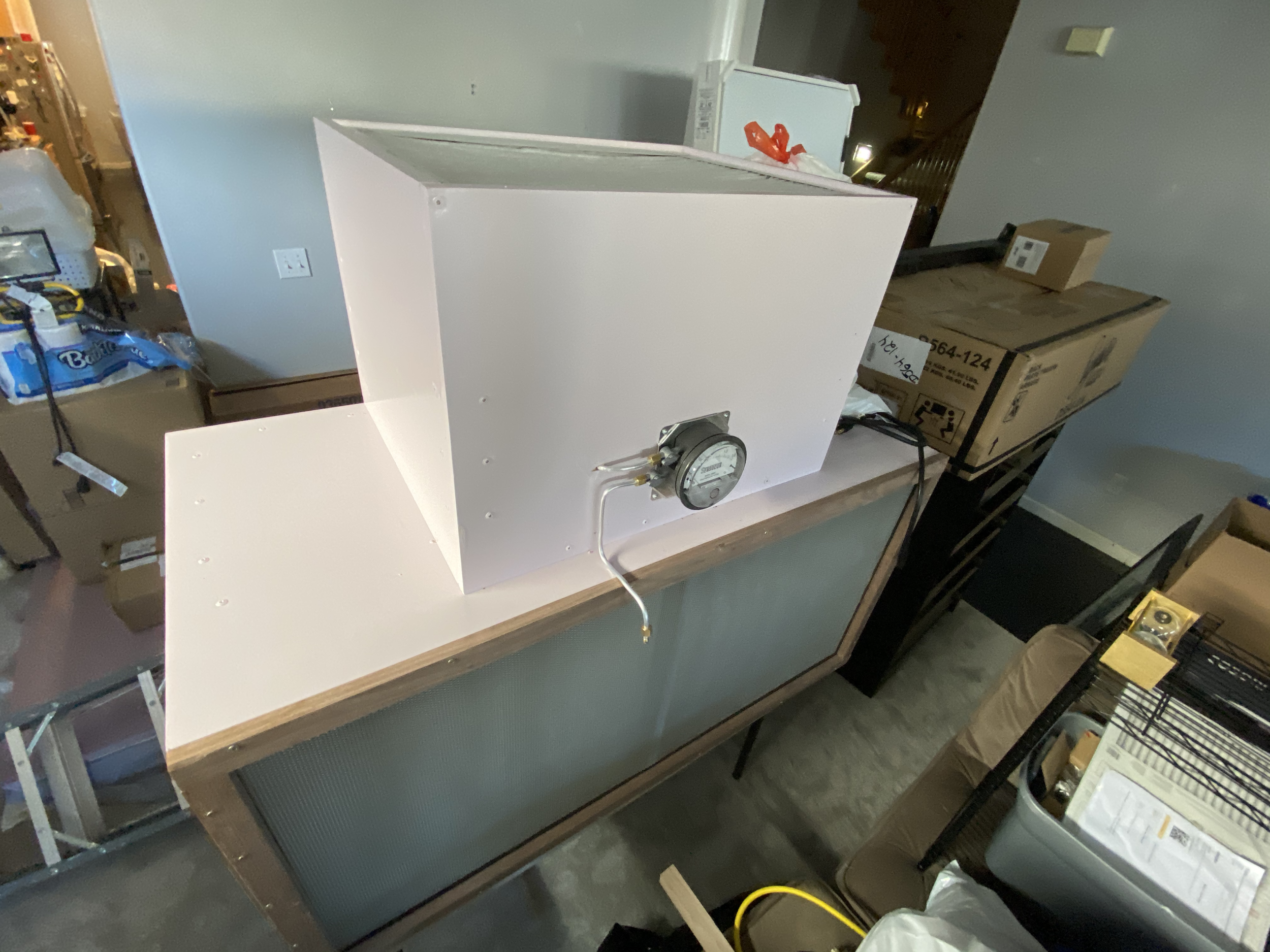

I show him a few videos, we discuss the idea maybe 47 times. Then we came up with this. Assumptions made upfront:

We want to create a positive pressure room.

A filter from Home Depot has a negligible, ~1 psi pressure drop.

Up next:

Find the right size / dimensions / test specs HEPA filter for a reasonable price.

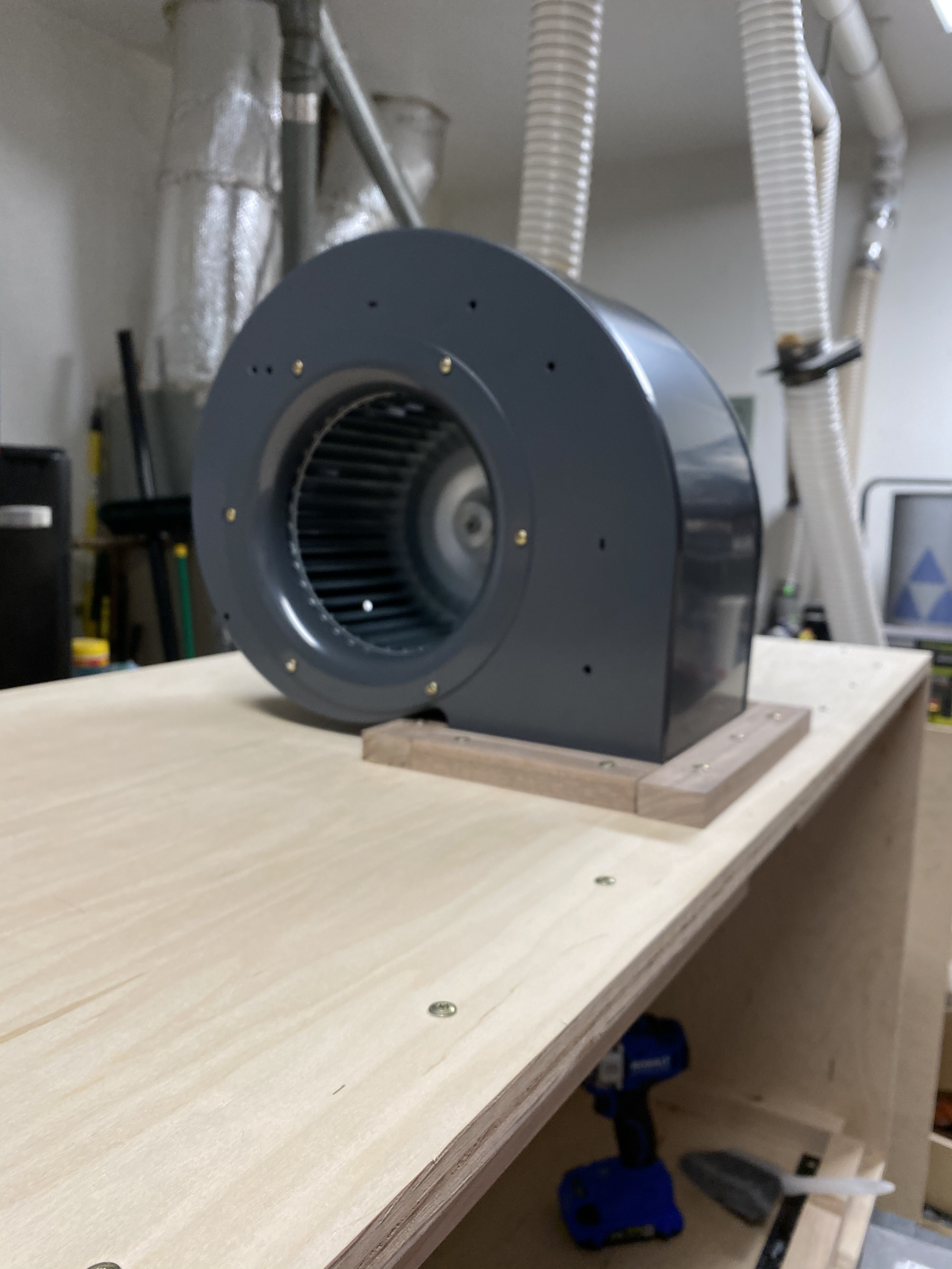

Using empirical fan data, find a blower fan that has a power range such that your HEPA filters square area can achieve laminar flow

Choose and buy electronics that fit the fan

Choose and buy wood for the casing

Build it in the correct order. Caulk everything.

My Specs:

size: 24 x 36 x 6 ; wood

rating: 99.7%

features: pre-filter, filter change indicator, anti-fungal, anti-bacterial paint hand painted inside and out, walnut casing, on/off switch

Is it working out?

We use it for E V E R Y T H I N G— from making syringes, inoculating liquid culture jars, inoculating grain jars, inoculating fruiting substrates, pouring agar dishes, inoculating agar and cooling anything that has been sterilized in the pressure cooker.

The biggest pain point was moving it— it was extremely heavy! And since we shuffled so much in the past year, it wasn’t moving it just once. Somehow, someway, we managed to get it upstairs. Otherwise, it can be loud and it does make the room hot due to the blower fan.

We have lots of fun using it and it works great, underneath our setup is our old kitchen table (it was difficult finding a solution to support it) with a cover and vinyl on top for easy cleanup. We keep isopropyl alcohol on deck at all times too.